Innovative Solutions – Ductile and Chrome White Iron Castings

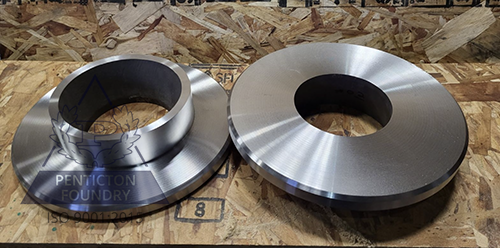

Established in 1935, Penticton Foundry, located in Penticton, British Columbia creates, among other things, ductile iron castings and high chrome white iron castings of exceptional quality and durability for clients across North America. With its commitment to innovation and design, Penticton Foundry’s highly skilled workforce can deliver custom work and specialty design on time and on budget.

We offer a full-service foundry, thus ensuring product consistency. Whether it’s complete, on-site CAD design, pattern making facilities, quality controlled alloy composition or precision chrome white iron castings, we know that our customers value our excellent service and dedication to making their product better. Our established, long-term relationships with our clients have transformed us from a local to international provider of castings and services.

We offer several competitive advantages that result in specific benefits for our customers. Contact Us and get started with one of our experienced sales consultants today.

News

Chute Liner Success in a Canadian Mine

on February 28, 2024High chrome white iron chute liners outlast AR 400 steel plate by 6x in a Yukon mine. Read the success story to find out more.

Why People are Changing from Ni-Hard to High Chrome White Iron

on January 23, 2024This blog explores why people are changing from Ni-Hard to high chrome white iron for abrasion resistant applications. Learn more today.

ASTM A897 Grade 3 175-125-04 ISO 17804, EN-1564

on December 4, 2023This data sheet focuses on ASTM A897 Grade 3 175 – 125 – 04 austempered ductile iron. It offers notes on composition, physical/mechanical properties and applications.