Austenitic Ductile Iron ASTM A439 Grade D2 58-30-8

on June 14, 2017Austenite is a high temperature constituent of the microstructure of iron castings. Most alloys transform to other constituents when cooling to room temperature. This transformation involves a fairly large volume change and is stressful to the castings. By drastically changing the chemistry (not heat treatment) we can engineer castings to stay fully austenitic at room temperature. This allows a casting to be cycled between cold and hot without going through a stressful phase change.

Composition

|

|

C |

Mn |

Si |

Cr |

Ni |

Cu |

Mo |

Mg |

|

Min% |

2.5 |

0.7 |

2.35 |

1.75 |

18 |

|

|

0.035 |

|

Max% |

3.0 |

1.25 |

2.7 |

2.75 |

22 |

0.2 |

0.1 |

0.055 |

Physical and Mechanical Properties

|

UTS |

58000 |

|

TS |

30000 |

|

%Elongation |

8% |

|

Hardness |

139-202 |

|

Density lb/in3 (g/cm3) |

0.268(7.41) |

|

Thermal Conductivity Btu/hr·ft·F (W/m·K) |

0.032 |

|

Specific Heat at 70F Btu/lb·F (J/Kg·k) |

|

|

Coefficient of Thermal Expansion Ɛ/F(Ɛ/C)X106 |

10.4 |

|

Melting Temperature (F) |

2250 F |

|

Compressive Strength Ksi (MPa) |

200 |

Impact Properties

Notched Charpy Impacts @ 70F = 12 ft-lb

Austenitic Ductile Iron Design Benefits 1

Austenitic ductile iron castings, also known as Ni-Resist, can be used in a wide range of applications because of the specific chemical, mechanical and physical properties. Ni-Resist is beneficial because of the following properties:

- D-2 is the most frequently selected grade, and excels in applications requiring corrosion, erosion and friction wear up to temperatures of 1440F(760C)

- Good strength, ductility and oxidation resistant at high temperatures. Ductile Ni-Resist is a chromium bearing type of the ASTM A439 grades which can provide sound mechanical properties up to 1475F (800C)

- Ductile Ni-Resist retains toughness at low temperatures

- Controlled thermal expansion, with the addition of Moly (Mo) D-2 has creep and stress-rupture strengths that are on par with, or exceed, cast steels

- Controlled magnetic and electrical properties

- Good castability and machinability

Applications:

- Valve stem bushings

- Valve and pump bodies

- Salt water and caustic services

- Air compressor parts

- Heat treat skirts and grates

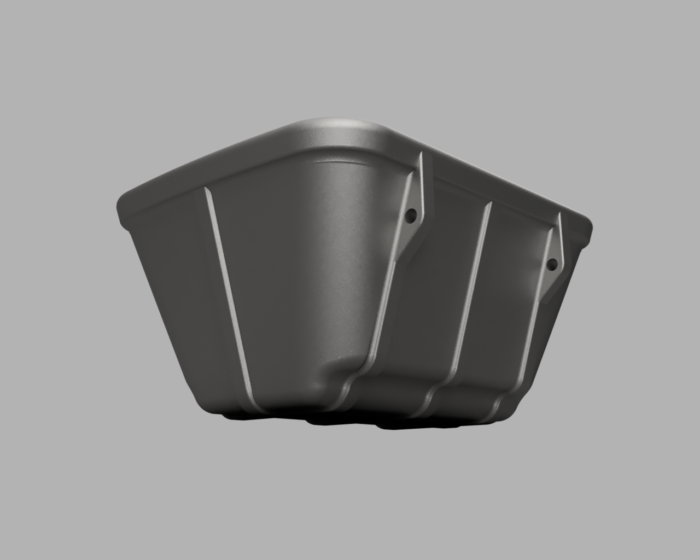

- Turbo charger housings

Read: For more information on austenitic ductile iron please read our webpage.

1“Ductile Iron Data” Ductile Iron Society