Rapid Cross-Sectional Changes in Ductile Iron Castings

on November 15, 2022Ensuring Ductile Iron Casting Performance

There are a number of design mistakes that can compromise the performance of a ductile iron casting. One mistake - rapid cross-sectional changes – is particularly problematic.

Note: Ductile iron (ASTM A536) can be used in any number of applications across almost every industry. It is generally easy to cast, exhibits a good strength to weight ratio, and has a low cost per unit of strength.

What Are Rapid Cross–Sectional Changes?

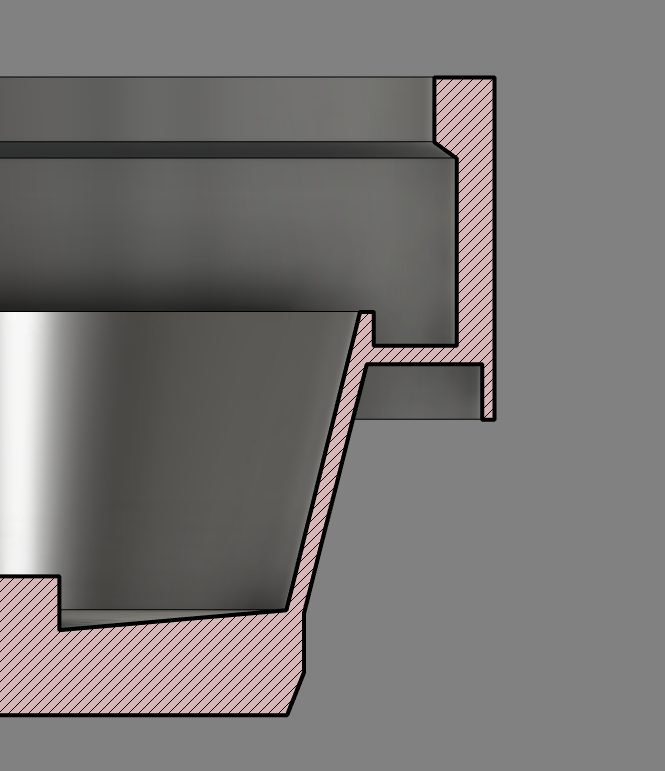

Rapid cross-sectional changes occur when a part’s design does not allow its dimensions to increase in a consistent manner toward a location that can be supplied with feed metal via the riser feeder. This compromises the casting’s uniform wall thickness.

The image to the right shows an example of a part that is difficult to feed due to rapid cross-sectional changes. The thicker sections at the top and bottom of the part are isolated from each other by thin sections. These thin sections will not allow metal to flow from a feeder, and so the foundry is forced to come up with a solution to produce a shrink-free casting.

Why Uniform Wall Thickness is Important

Reason 1: Soundness of Casting

Ductile iron shrinks as it solidifies. Uniform wall thickness can help ensure the shrink is eliminated, or moved to a location that will not affect the casting’s performance:

- Having the thicker sections near riser-feeders allows the liquid shrinkage to be fed

- The section thickness should be greatest under the riser-feeder, and reduce as the section moves away from the riser feeder

- If a section change is unavoidable, ensure that the thicker section is accessible to feed metal

Reason 2: Strain in Casting

During solidification, a casting with rapid cross-sectional changes can develop strains in the lighter sections. By redesigning the casting to be uniform in thickness, shrink defects can be avoided and strains can be eliminated from the thinner sections.

Reason 3: Cost/Weight of Casting

If heavy/thick sections can be reduced in size, this will not only improve the soundness and lessen the strain, it will also reduce the weight of the casting and the cost of the casting.

Pro Tip: At a particular point, it can be more cost-effective to cast rather than to fabricate, particularly if a number of steel fabrications must be made. This article outlines some of the advantages of the casting process, including design assistance and pattern creation.

Read: To learn more about ductile iron, check out our ductile iron webpage. It also includes links to specific ductile iron data sheets for more information.