Chrome White Iron Liners

on October 14, 2015

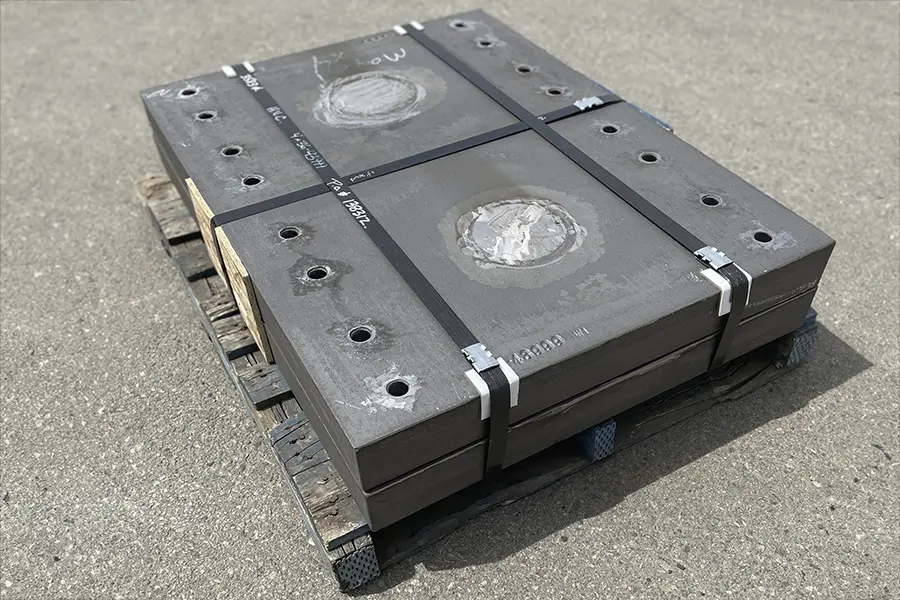

Chrome white iron liners, with their combination of martensite and carbides, offer superior abrasion and wear resistance. They can be found in the mining, potash, concrete, cement, recycling and the pump industries. Chrome white iron liners can also be combined with a steel pressure boundary for the hydrotransport of severe slurry in the Oil Sands.

We use a proprietary process to create our high chrome white iron products. Interestingly, there are a number of myths and facts about chrome white iron, the least of which is that it cannot be machined. Other myths include that it is too brittle for applications involving impact or that it won’t outperform materials of a similar hardness. None of this is true. Indeed, chrome white iron will often outperform other wear options, including AR plate and chromium carbide overlay.

Read: To understand why chrome white iron is so abrasion resistant, read this.

Why Use Chrome White Iron?

- Superior wear resistance - particularly against gouging and abrasion

- Corrosion resistance is much higher than other options like AR Plate

- Chrome white iron liners are recyclable

- Cost savings – fewer shutdowns due to extended service life

- Liners can be made thicker in high wear areas

Case Study: Chrome white iron in the mining industry

High Chrome White Iron Liners

Features

- Can be cast to size required

- Any bolt-hole pattern

- Some applications (like loaf liners, grizzly bars) can be slotted to fit without bolts

- Inserts can be cast in for easy drilling/tapping or plug welding

Advantages

- Alloy selected to provide best possible wear characteristics at the price point required

- Casting hardness profile is consistent throughout, providing predictable wear life

- Easy assembly into chute, conveyor, box, vessel, pit, etc.

- 100% recyclable

Benefits

- Many times more wear resistant than AR Plate

- Cost savings - Increased time between shutdowns

- Cast to size means less work for installation team

- Canadian engineered and manufactured.

Below are some drawings of Penticton Foundry's chrome white iron wear liners. If you don’t see the size you need please contact us, we may have built a new pattern recently. Keep in mind that the patterns for custom liners are very affordable if you require a unique shape.

11/2 Inch Thick Wear Liners

Learn More: 11/2 Inch Wear Liners

2 Inch Thick Wear Liners

Learn More: Standard 2 Inch Wear Liners

8 Inch Thick Wear Liners

Learn More: Standard 8 Inch Wear Liners

Check out our Gallery to see some of our liners and other products.