White Iron Cyclone Used in Oil Sands

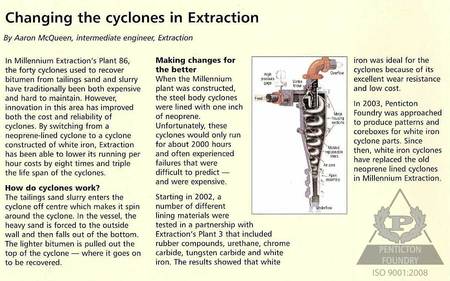

on July 30, 2009Our customer anticipated a three times increase in life span when they switched from neoprene lined cyclones to white iron cyclones in 2004. Running costs per hour would be 8 times lower and they would cost a third of the price of the originals.

Don’t we all dream of results like that?

In fact, the results are even better – 17 times savings:

“Based on recent UT measurements and hour tracking, I estimate the white iron cyclones will last for about 12,000 hours. The previous estimate was 6000 hours but now that we have more data, the results look even better.

We currently have 7 cyclones with more than 6000 running hours with the most used cyclone with 8200 hours. We haven’t changed any cyclones out since we started installing them in 2004. The recent UT survey had only one survey point that was below 5/8″ (original was 1″ for most areas) – the current plan is to run these cyclones until they reach 1/4″.

“Just as a comparison, the old rubber lined cyclones lasted about 2000 hours and were close to 3 times the price in 2004. If the cyclones do in fact last for 12,000 hours, then the cost savings from changing the cyclones to white iron will be about 17 times which has resulted in a significant materials savings in Plant 86.

With these great results, we can see that we can achieve savings in other areas of the plant by changing to white iron. We’ve recently ordered some white iron “spun cast” bypass elbows and a tailings elbow. And we’re going to order some white iron liners to replace the rubber liners in the cyclone inlet spools. In the future, we may also order some white iron “bolt on bells” for the sep cell underflow nozzles….”

And it can only get better. The cyclones are only about halfway through their expected life span!