Bi Metallic Wye and Lateral Hydrotransport Spool Update

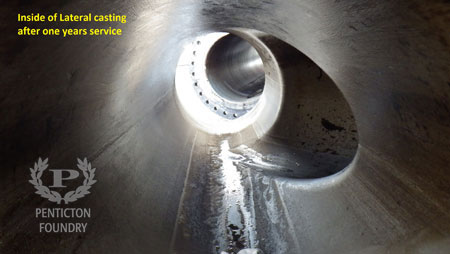

on September 22, 2012The Wyes and Laterals were recently inspected after twelve months operation. (Read about the Bi Metallic Wye and Lateral installation here)

During a recent outage we were able to record how the castings stood up to a year of service. The media being pumped was hot water, bitumen, quartz/feldspar sand mixture with 5” minus rocks.

During a recent outage we were able to record how the castings stood up to a year of service. The media being pumped was hot water, bitumen, quartz/feldspar sand mixture with 5” minus rocks.

Wear on the switching wye leg and the downstream leg was negligible, the only recorded wear was in the 5-7 o’clock position at the bottom of the upstream spool.

The customer was very pleased with the finding and as a result has not scheduled another inspection for a year.

These spools are used in hydrotransport of bitumen and ore, similar CCO (chromium carbide overlay) spools are used downstream in tailings. Typically the CCO will require weld repair after six-week service, if no weld repair takes place the spool will often wear through the pipe after nine weeks.

The customer has seen a dramatic increase in wear life and decreased cost of maintenance and lost production.

As the result the customer is looking for other applications to utilize white iron in their facility.