The Myths of Chrome White Iron – Brittleness

on July 25, 2017The Myths of Chrome White Iron

There are a number of myths about chrome white iron. One of the most common is that high chrome white iron is too brittle for many applications

The Origin of This Misunderstanding

The grades of high chrome white iron represented by the ASTM A532 standard are considered brittle because they have virtually no elongation (ductility), leading people to believe that high chrome white iron is too brittle for their application.

The Reality

The reality is that high chrome white iron is highly effective in many applications that involve not just abrasion, but also impact.

The Data

Penticton Foundry has tested its Granite25 high chrome white iron alloy in simple bend tests, and the results provided ultimate tensile strength (UTS) values from 116,000 psi – 130,000 psi, which are typical values for this material.

The high chrome white iron alloys don’t exhibit any significant yielding during a tensile test,  so the traditional tensile test may give variable and misleading results. As an example, we have conducted some traditional tensile testing of our Pliant25 high chrome white iron alloy and have measured results from 92,000 psi – 123,000 psi. These results are included for interest sake only, and to demonstrate the need to use the bend test to categorize the tensile strength of chrome white iron.

so the traditional tensile test may give variable and misleading results. As an example, we have conducted some traditional tensile testing of our Pliant25 high chrome white iron alloy and have measured results from 92,000 psi – 123,000 psi. These results are included for interest sake only, and to demonstrate the need to use the bend test to categorize the tensile strength of chrome white iron.

Typical Uses

The high chrome white iron alloys are not typically used to produce a stressed-member that is part of a machine or structure. Think of a steel I-beam that might be used to hold up a truss in a building. Obviously, high chrome white iron is not the correct alloy for such an application.

Any time, however, abrasive media is running over a surface, high chrome white iron can potentially be the best choice:

- Blow bars for horizontal shaft impactors (which take a massive amount of impact)

- Anvils and throw shoes for vertical shaft impactors

- Gyratory crusher concave liners (massive impact load)

- Pump casings (under pressure)

- Impellers

- Suction liners

- Elbows, laterals, wyes

- Liners for ball mills and chutes

Read: “High Chrome White Iron Nut Sleeve Outlasts Alloy Steel 6 Times” to read a case study that illustrates high chrome white iron’s superior abrasion resistance.

Design Tips

- Thickness

The key, when designing with high chrome white iron, is to allow for the appropriate thickness. To withstand the pressure or impact that a part will be subject to, the correct section thickness must be determined and specified (obviously, there are weight restrictions when designing a thick part). Also, the thickness is one of the criteria that will determine the useful life of the product, as chrome white iron parts are always designed to wear out and be replaced. - Support

The other main consideration with high chrome white iron parts is to adequately support them. This can be done by machining the fit-side of the casting to fit the support. Some other options:

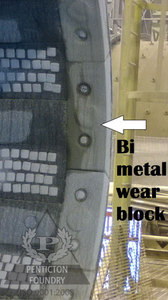

- Casting the chrome white iron onto a steel support (making a bi-metallic part)

- Joining the chrome white iron to a steel support (e.g. via silver solder).

- Filling the gap between the chrome white iron and the support (with, for example, an epoxy).

Read: “The Top 5 Design Mistakes in High Chrome White Iron Castings” for more design tips to maximize your ASTM A532 casting performance.

Final Note

There are many ways to engineer a high chrome white iron part to be able to withstand high impacts and to gain all the benefits of its extraordinary abrasion resistance. Check out our chrome white iron webpage, or contact us today to learn more.