High Chrome White Iron vs Cast Iron

on June 17, 2025

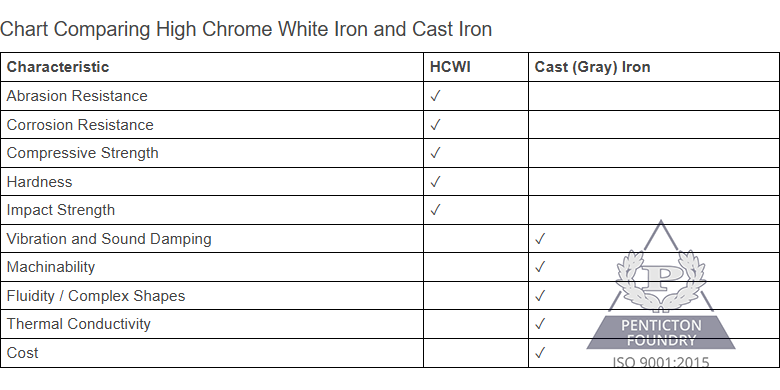

This blog compares high chrome white iron, ASTM A532 and cast iron, specifically ASTM A48. Whether it’s abrasion resistance, machinability or compressive strength, the alloys are quite different. For a quick summary, scroll down to the bottom of the blog and check out our chart.

Key Differences of Chrome White Iron and Cast Iron

- Abrasion Resistance – Under any conditions, high chrome white iron, ASTM A532, is superior in abrasion resistance to cast iron, ASTM A48. The microstructure of high chrome white iron is composed of carbides (chromium carbides and complex carbides) and martensite. This makes high chrome white iron extremely resistant to all forms of abrasion, especially gouging abrasion. Cast (gray) iron, A48, has flakes in its microstructure which provide no resistance to gouging, although the graphite does provide some lubrication. In addition, the ferrite in its microstructure is quite hard, and not very abrasion resistant. This means that cast iron, typically, would not be chosen for an application requiring abrasion resistance.

Read: To understand why chrome white iron is so abrasion resistant, read this.

- Vibration and Sound Damping – Cast iron’s microstructure has a network of graphite flakes, and usually a combination of ferrite and pearlite. This network of graphite flakes does not let sound or vibration pass through, creating what is colloquially called a “dead zone” and acting like insulators. This makes cast (gray) iron, A48, extremely good at vibration and sound damping. For applications like machine-tool bases, cast iron is an ideal choice. High chrome white iron would not be used in an application requiring vibration and/or sound damping because the microstructure of high chrome white iron allows sound and vibration energy to pass through it unhindered.

- Corrosion Resistance – High chrome white iron has excellent corrosion resistance, which increases as the chromium content increases. When an application requires both corrosion and abrasion resistance, high chrome white iron is a good choice. In contrast, cast iron does not have enough chrome in it to build up a protective layer, or passive film, that protects the metal from oxidation, making it an unlikely choice for a corrosion resistant application.

- Machinability – Cast iron is one of the most easily machined alloys. The network of graphite flakes provides natural lubrication during the machining process. High chrome white iron, on the other hand, is an extremely hard alloy. This can make it difficult to machine for many shops, requiring different machines and tools than for machining cast iron. Alloy design, tool design and the engineering of the machining process can provide solutions for the proper machining of chrome white iron.

View: There is a myth that chrome white iron cannot be machined. This is not true - watch this video.

-

Compressive Strength – Generally, high chrome white iron has a higher compressive strength than cast iron. It would not, however, typically be used solely for its compressive strength. Instead, an application needing abrasion resistance, combined with compressive strength, such as when the parts are loaded with massive quantities of media, would be where chrome white iron would shine. Cast iron’s compressive strength, however, should not be discounted as it is typically more than 3x its ultimate tensile strength. This makes cast iron a perfect material for machine bases that support a lot of weight.

Pro Tip: This is not the case for steel, which is typically stronger in tension than compression.

- Fluidity (Complex Shapes) – Cast iron, ASTM A48, is more fluid than high chrome white iron. This allows very complex and thin shapes to be made from cast iron. High chrome white iron is still reasonably fluid, and intricate shapes (like pump impellers) can be made from this alloy. The design of the alloy will allow for more or less fluidity, so be sure to work closely with your foundry of choice.

Read: To learn more about designing with chrome white iron read The Top 5 Design Mistakes of High Chrome White Iron Castings.

- Hardness – High chrome white iron alloys are much harder than cast iron alloys. In fact, cast iron is often used for applications because it is not hard. The lack of hardness allows cast iron to be easily machined with standard cutting tools. When using high chrome white iron in an abrasion resistant application, quite often hardness is the only property specified. By measuring hardness before being put into use, one can get a good approximation of the state of the microstructure, which can help gauge the longevity of the part.

Read: To read about the hardness myth of chrome white iron, click here.

- Thermal Conductivity – Cast iron has excellent conductivity because of the network of graphite flakes. This is one of the main properties that engineers/designers take advantage of when specifying cast iron in equipment. High chrome white iron, on the other hand, does not have a high thermal conductivity, and should not be cycled through large temperature changes as this would add a lot of stress, and could lead to cracking.

- Impact – Impact strength is also known as toughness. Both high chrome white iron and cast iron are not selected for applications requiring high impact strength. Cast iron would have a lower impact strength than chrome white iron.

Read: There is a myth that chrome white iron is too brittle for many applications.

- Cost – Cast iron will cost less than high chrome white iron. This is because high chrome white iron contains a lot of chromium, which is an expensive raw material. It can also contain molybdenum, nickel, and copper, as well as other expensive raw materials. In addition, it is more difficult to process through the foundry.

Read: To learn more about chrome white iron, click here. To learn more about gray cast iron, click here.